|

Eng. Shereen Mosallam Symbios Consulting Manager OPEX society Advisory board, Lean Six Sigma MBB, CPF, Qualified SCOR instructor, 20 keys consultant |

Supply Chain Excellence Conference 11th March 2017 – Cairo - Egypt |

Dr. Joseph Paris Founder of Operational Excellence Society and Chairman of the XONITEK group of companies |

It gave us a great pleasure that OPEX and Symbios managed to organize its first Supply Chain Conference. As part of our social commitment to Youth; we were keen to bring the top companies in this field recognized by international audit organizations as Gartner such as Unilever Meshreq and Schneider Electric ranked 1st and 16 respectively.

We would like to thank our Key Speakers; who enriched the conference with their experiences and openness to the audience questions, making it an effective learning experience to our audience.

Also, we felt honored by our sponsors’ confidence in Symbios and OPEX organizing this conference and their active participation by the teams of Oracle, KAPCI and LUCRAM. We had the privilege that among our audience were key figures and top experts in their fields as LEONI, Egypt Foods, Union Air , Electorlux and Al Araby Group just to name a few. Our youth participants showed great desire to engage and understand how these big companies operate a complex yet efficient full integrated supply chain systems.

The conference was well received and we are keen to further improve our pre-registration process and manage sessions more efficiently in the future to meet all participants’ needs.

We’ve enjoyed the strong beginning made by Eng. Sameh Sabry , Unilever giving us insights on Supply Chain in FMCG and their “Make to Stock” approach, while Eng. Mohamed Saied presented Oracle as Enable of tools required to make supply chain live and adopting digital or technological advances using Internet of things , increasing visibility of data for quick decision Making. Eng. Sameh El Gabary and Ms. Nermine Abou Helwa tackled Supply Chain from “Make to Engineering” approach which showed a high level of complexity, insights of Schneider Supply chain Model, sourcing strategy and supplier performance management. Eng. Mohamed Nassef presented LEONI wiring system Supply Chain Management which has a special unique nature of being No 1 in automotive industry and run Make to Order supply chain efficiently as all its production is addressed to foreign markets.

We’ve ended our day with a short yet very enlighten session by Dr. Aly Awni on Socially Responsible Supply chain, showing the difference between doing charitable activity and running an effective sustainable development role. He presented several successful cases run by companies as Unilever, Danone etc.. That enabled less privileged people opportunity to work and generate income for themselves as distributors or suppliers to these companies. Important lessons were discussed and I personally benefited from and enjoyed and encourage all our society members to check our website for the full presentation and looking forward to your active participation in our coming events. Finally thanks to Symbios team and our youth volunteers for all the hard work made in preparation and during the day to make every guest welcomed and enjoying the experience.

|

About the Speaker

|

Supply Chain Management End - End Concept • Supply Chain Management embraces Suppliers and Customers to offer an End– End perspective • Effective Supply Chain Management addresses VUCA ; we are working in Volatile, Uncertain, Complex and Ambiguous Environment. Supply Chain Excellence results in savings; as it pushes companies to reduce WASTE, develop their suppliers and consider reducing cost at every stage of the complex process. In Unilever, we develop our suppliers and encourage them to bring their investments to Egypt as they will enjoy competitively cheap labor and reasonable operation cost while guaranteeing that we take their production as well as other competitors in the region. It’s a win win situation for Unilever to reduce shipping of raw material cost and duration and for the country to bring more investments in. Unilever has built a hub in Alexandria that one of its factories will dedicate its production to export purposes only. • Unilever , over the last 5 years, has been improving its rank in Gartner Supply Chain Excellence Ranking until became 1st in 2016. It’s the most prestigious award in this field. It’s based on Gartner, peer opinion and auditing. • Unilever has an excellent record of sustainable development in Egypt among other branches. Zeinab initiative is an example of helping women in unprivileged governorates sell Unilever products from home and generate income. Similar to this they provided young men with bikes to sell their products in alleys and small villages and generate income. • In the environment front, and among many initiatives, they consider reducing their footprint and impact; for example by reducing water consumption in their business thus moving forward more concentrated detergents. |

|

About the Speaker

|

What’s holding back your End-to-End Supply Chain Operating Capabilities? Over the years, Oracle has developed solutions and incorporated processes of supply chain as forecasting, planning and production. Recently and in order to cope with the technological advances Oracle is moving towards Digital Supply Chain. As the regular supply chain focus is reducing cost, digital supply chain increases efficiency and agility of the business dealing with all embedded processes. It adopts solutions to make the client/customer the center where all processes are connected too. Furthermore using internet of things we can monitor all phases of supply chain. For example, it tackles transportation and delivery of the goods. Once a transaction starts it manages and monitors data from all departments as well as manage the supplier capability of meeting the request. If received a signal from the forklift that there’s a problem though the net, it would be shown at other parties as production, planning and enables us to contact the customer and avoid possible complaints. Visual Analytics reports are made easier to top management, stakeholders within the supply chain as suppliers, producing department, marketing etc. Thus achieving better alignment between financial planning and production planning and better alignment of Key Performance Indicators. The Digital Supply Chain can play as simulator to different scenarios that could happen and increase business unit’s agility dealing with them in reality. This would result of being proactive rather than reactive. Oracle cooperates with international auditors of supply chain as Gartner in forecasting future intelligence, demand and how it can increase company maturity and capitalizes innovation. of things and will be shown at every department for example the quality, maintenance department . Oracle provides not only solutions but rather an insight to the future of more agile supply chain |

|

About the Speaker Nermine Abu Hulwa

|

How to manage “Engineer—Order” Supply Chain and addressing the challenges? Schneider has the most complex supply chain which vision is delivering sustainable competitive advantage being a valued customer for the best in class suppliers and a function of choice for our employees. They develop their Supply chain people, guarantee availability of their high quality products to their customers, develop suppliers capability and control logistics cost. Schneider sourcing operates around 4 main functions: 1) Commodity markets 2) supply chain regions 3) Transversal and support functions and business. They have two types of sourcing: 1. Production Sourcing which is an operational 1. Global performance with suppliers which aim to boost purchasing performance on customer critical dimensions, boost global efficiency which impact on industrial cost and working capital and reducing development cost and boost savings. 2. Localization as Schneider focuses on dealing with local partners who can grow with the company and drive sustainable global performance. 3. Suppliers concentrations to ensure flow between suppliers and factories 4. Quality value engineering which aims to optimizing the cost with no impact on quality or process sustainability. QVE is involved in Redesign to cost—material wastage, changing material, production process reengineering, developing new products and Lean Manufacturing. How to manage “Engineer—Order” Supply Chain and addressing the challenges. Schneider supply chain process:

• Among many initiatives to support local suppliers and develop them, Schneider has been engaged with Industrial Modernization Center in Egypt to develop local suppliers. Also Schneider participates in Engineering faculties and syndicates, offering technical programs and certification for technicians on electric—graduate program of 20-25 student every year to develop them and choose the best of them to join Schneider. Finally Schneider has been in Egypt over the last 30 years and participated in mega projects leaving a legacy of running a state of art technologies and effective yet extremely complex supply chain process. |

|

About the Speaker Mohamed Nassef Head of Supply Chain in Leoni Wiring Systems Egypt and Management team member Board member of the Engineering Export Council of Egypt (EEC-EG) Holder of MBA and BSc of Electric Engineering. Over 24 year experience in Supply Chain Management

|

LEONI Wiring Systems Supply Chain Management LEONI’s global supply chain vision is to satisfy all our stakeholders. In LEONI Egypt the vision is to maintain customer satisfaction trough developing supply chain members and reducing cost by eliminating non value added processes. Every day, supply chain team must provide an idea to be displayed and ranking is given according to ranking of these ideas and key performance indicators and total savings between departments. Competition in our case is between LEONI’s different business units across the world. Supply chain elements start with procurement, inbound transportation, raw material inventory , production scheduling, finished goods warehousing, and outbound transportation and distribution, Supply chain network in LEONI starts with the supplier providing 10% of raw material, 90% comes from LEONI’s raw material consolidation centers which needs to be very close to the customer and this is the main area we constantly work on improving . Our main consolidation centers are in Germany and UK near our customers in this region as BMW , Jaguar , Land rover and Mercedes . LEAD Time in Automotive business is crucial and sensitive, thus we work on reducing it to be only 1 week, production cycle takes 1 week, delivery by shipping to LEONI warehouse takes 2 weeks and 1-2 weeks inside the warehouse . Safety stock is only 1 week instead of 3 weeks back to 2 years ago. Budgeting process, sales and operation planning every month, MPS Master Production Schedule run on a weekly basis, Sequencer is more of a daily plan. Generate supplier order and receive its confirmation, some customers receive dedicated container thus shipped by sea however other shipping is usually done by airfreight. LEONI Egypt Supply chain challenges and ways of overcoming these challenges: • Geographical location in Egypt : Raw material control is another challenging area especially that we deal with other LEONI branches as Tunisia and Morocco and both have better shipping facilities to Europe as for example there's a daily ferry from Tunisia to Europe. LEONI Egypt • Internal material flow is very dynamic as customer changes their requests all the time., sometimes every day, We’ve taken several actions to improve all aspects of the process including transportation and adopted multi model options that may be a bit expensive that combines for example air freight with sea freight . However with prioritization of shipped goods according to their value, maximize the volume of goods to match the container dimensions have resulted of good savings. • As each supplier has his own packaging that we worked on standardizing it as well as material classification to ensure best use of our shipped container. • LEONI has developed its own IT automated solutions that provides priority list of the products needed from each production station among many analytics reporting features to take the right decision at the least possible time. |

|

About the Speaker Dr. Ali Awny

Director at John D. Gerhart Center for Philanthropy and Civic Engagement Over twenty years of management consulting, system development, and business process improvement experience focusing on supply chain management and business operations/logistics in different industries. Recently, Awni has taught operations and supply chain management courses for EMBA and executive education at Egypt, Romania, and Germany.

|

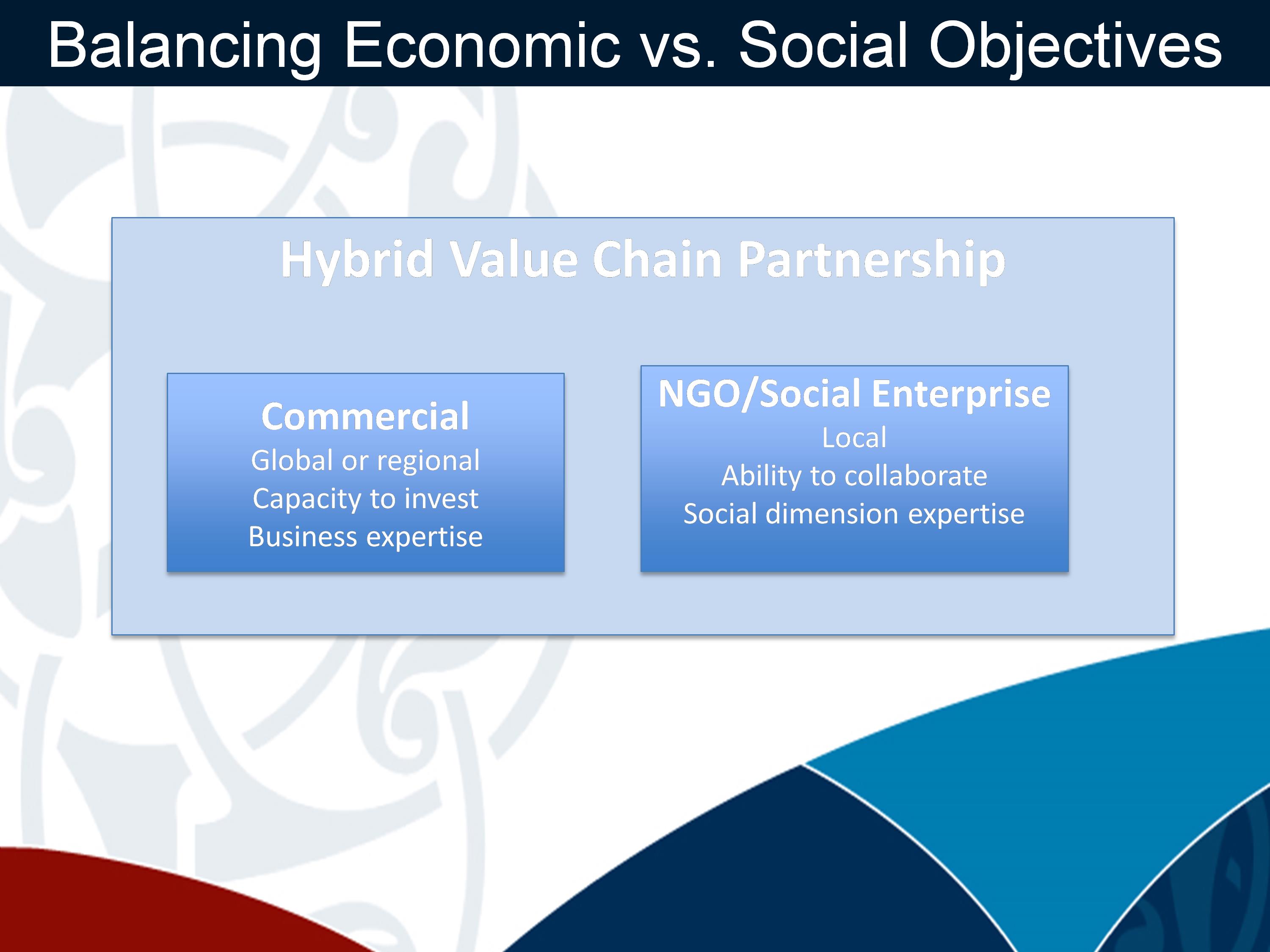

Socially Responsible Supply Chain Everyone agrees that the main purpose of making a business is to make profit and its as important as oxygen is to a person, however you don’t live to just breath oxygen thus it can’t be solely separated from the welfare of shareholders, employees and stakeholders and thus big companies are moving towards sustainable development . • Ethical supply chain should communicate ethical behavior and fair treatment to all its stakeholders. •Supply chains must satisfy societal expectations and regulations as : •International Labor Organization (ILO) Conventions, •United Nations (UN) Universal Declaration of Human Rights,, •World Responsible Apparel Production (WRAP): independent, non-profit organization dedicated to the certification of lawful, humane and ethical manufacturing throughout the world. Making profit and reducing cost shouldn't jeopardize safety of the workers. To become a company of the future you should implement “Inclusive businesses which are private sector investments specifically targeting this low income market with the double purpose of making reasonable profit (i.e. an internal rate of return of 8-20%) and creating tangible development impact through the provision of sustainable decent jobs and better income opportunities, as well as services that matter for the poor’s life.”Many Large “ “Corporate Social Responsibility is the continuing commitment by business to contribute to economic development while improving the quality of life of the workforce and their families as well as of the community and society at large.”

|

Socially Responsible Supply Chain

Dr. Awni presented successful sustainable development projects carried out by Unilever as “Zeinab” that targets to developing women in poor areas to train them on business basics and sell the company’s products in their communities or from home to generate income. Danone has its program to empower small producers of milk collecting it from them at fair prices with guidance on how to increase volume and maintain safety of the milk. Fair Trade is a collaboration with an Italian NGO to promote handmade crafts at villages to generate income, market their products and help preserve the heritage of handcraft in Egypt. They have 2 outlets in Maadi and Zamalek and promote their goods online too. We have many hand craft spots in many governorates in Egypt that needs to shed light on , promote their goods as unique handcraft not to be compared with mass production or price comparison to Chinese goods. Every Company must engage in developing the community it operates in; through the services it provides. It’s essential to include sustainable development activities within its business plan.

|

|

|

|

|